U2 NAH Bearing Overhaul

Industry: Power & Energy

PROJECTS

Scope of Work

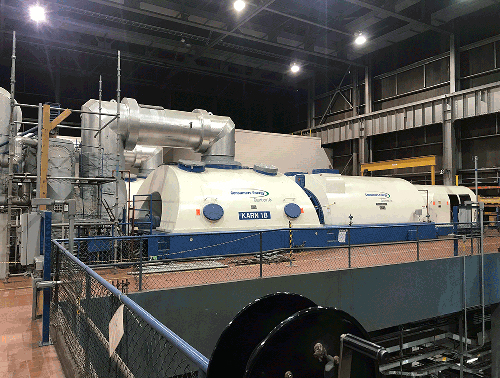

The Unit 2 North Air Heater main bearing experienced a catastrophic failure at the Monroe Power Plant. Located at the hot end of the air heater, the bearing itself is one of the largest in the world of its kind. Due to the urgency of the forced outage, planning and execution was critical resulting in work being performed around the clock until completion.

Serving as the onsite maintenance contractor, our team self-performed the removal and installation with millwrights, ironworkers and operators. In order to remove and replace the bearing, two – 300-ton jacks were used to lift and support the air heater shaft. In addition, a custom monorail system was engineered, fabricated and installed for rigging & transferring the bearing from the 6th floor to ground level.

As a strategic industrial maintenance partner for DTE, our team was engaged immediately based on our specific air heater expertise. With years of experience performing air heater outages, onsite crews and tools, strategic partnerships and experienced leadership, our team controlled the project planning, execution and overall safety for the outage. As a result, the outage was completed with no safety concerns or startup delays.